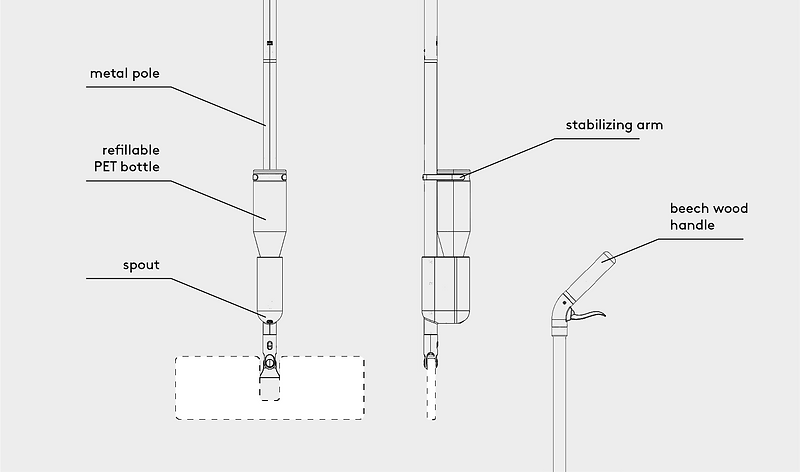

After design of the spray mop was nearly complete, it was ready to be optimized

The mop head was identified as an opportunity for plastic reduction

*Compared to an existing, owned brand spray mop head

Fusion360 was given preserve geometry, boundaries, and forces that the mop could experience

The software was tasked with creating the minimum necessary material while supporting the stresses

Fusion delivered several different (but not ready for manufacturing) solutions

To define the final concept, the three geometries were compared to find similarities

The major difference between the Fusion solutions and the final design is symmetry

The mop head’s ribs help create contact between the fabric mop head and the floor

The mop head rotates over 180° and the fabric pad is double sided